Supply Chain Management and Digital Transformation: the Past and the Present

Author: Professor Jukka Vesalainen, University of Vaasa

This paper discusses the role and opportunities of digitalization of supply chain management (SCM) in the context of traditional SCM practices. Is it so that digital transformation is about digitalizing all the traditional activities and processes of supply chains or, do we have to change the old practices or even develop completely new activities in order to take full advantage of digital technologies? To begin with, the paper makes a short overview (from the 1980s to the beginning of the twenty-first century) of the aspects that have traditionally been included in SCM in academic research. It is followed by an overview of the digital transformation of SCM. The paper ends up with a summary of the differences and similarities between SCM practices in the past and in the present.

The competition–collaboration continuum

Business relationships can be placed in a continuum that ranges from pure market-based relationships to deep collaborative partnerships. In market-based relationships, buyers use actively and even aggressively the supplier markets to buy cheap. This means that relationships between customers and suppliers remain undeveloped. On the other end of the continuum, in a partnership -type of a relationship, firms of a relationship cooperate intensively with each other and build common activity in the long run. The aggressive use of competition is not possible in a partnership, which is based on trust and common benefit. Thus, the competitive advantage of market-based SCM is replaced by collaborative advantage of integrated supply chains. In practice, however, competition and collaboration go hand in hand with varying degrees. This is called coopetition in the SCM literature.

SCM practices and key performance criteria from the 1980s to the beginning of the 21st century

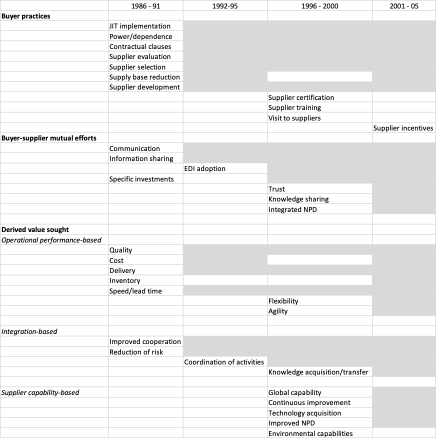

An article by Terpend et al. (2008) offers a good overview of the SCM activities and performance criteria that have been regarded as important in SCM from the 1980s to 2005. They approached SCM from the relationship perspective. Table 1 below summarizes the findings of their review on the following areas of investigation: Buyer firms’ SCM practices, mutual efforts by buyer and seller, and derived value sought (operational performance, integration, and supplier capability-based values).

Buyer firms’ SCM practices seem to be quite steady in terms of SCM activities. The basic list of activities ranging from JIT activities to supplier development been the same throughout the years. The third evaluation period introduced three new activities (supplier certification, training, and visits to suppliers). In the last period supplier incentives emerged as a new topic. Whereas buyer’s SCM activities have been quite steady, there seems to be more development realized in the area of buyer-supplier mutual efforts. Communication, information sharing, and specific investments seem to be the steady topics in this area. The first sign of IT and digital transformation came into the picture in the 1990s when EDI adoption appeared as a research topic in the literature. Later, in the third evaluation period, three new topics on collaboration emerged in SCM research: Trust, knowledge sharing, and integrated NPD. All the new themes highlight trust-based deep cooperation.

Table 1. The main topics on SCM based on buyer-seller relationships between 1986 and 2005 (adapted from Terpend et al. 2008)

What comes to the values sought through SCM, the basic operational-based values (quality, cost, delivery, speed/lead time) seem to be quite steady through the years. Flexibility and agility representing the values of a fast-paced business environment came into the picture in the late 1990s. The integration-based values representing cooperation as an objective have been important from the beginning of the evaluated period (improved cooperation and reduction of risk). Coordination of buyer-seller activities and later on knowledge acquisition/transfer have been added to the list of important values of integration. The third aspect of value sought in SCM, supplier capability-based values, emerged in academic research in the late 1990s and has ever since been a strong topic of SCM research.

The overall picture of the development of SCM, based on top academic research, shows clearly the rise of cooperativeness and supply chain integration as an important topic of research. It shows in the steady position of supplier development as an important activity of SCM. More importantly, the position of buyer-supplier mutual efforts has strengthened as a research topic. In that area, the important roles of communication and information sharing have been steady through the years. On top of that, trust, knowledge sharing, and cooperation in product development have been raised as new important areas of investigation. Buyer-supplier integration is also regarded a value as such. Improved cooperation, risk-sharing, and more recently coordination of activities and knowledge transfer represent clearly the importance of close cooperation as a target of SCM. Finally, the emergence of supplier competencies as an SCM target highlights the cooperation between buyers and sellers.

Digital transfer and SCM

According to the table above, the first IT or digitalization-related topic in SCM literature was Electronic Data Interchange (EDI), which appeared in the research at the beginning of the 1990s. A database search reveals that the top year for published articles on EDI was 2000. Ever since the number of articles has decreased, but even today EDI seems to be one topic that interests researchers. Parallel to EDI, research on supply chain digitalization started at the beginning of the twenty-first century. A search in the Scopus database (“supply chain digitalization”; research articles on business and management) showed 143 matches, the first two published in 2000. The real boom of published articles was 2020 when the number of publications rose to a completely new level (47 publications a year). The same trend is shown concerning the articles published in the discipline of Computer Science.

The literature review by Büyüközkan and Göçer (2018) offers a closer look at supply chain digitalization. According to their review, the most researched topics on SCM digitalization relate to big data, IoT, cloud computing, and digital supply chain as a general topic. Looking at the topics in newly published research articles it is also evident that themes related to blockchains and Industry 4.0 as a general theme are quite numerous. The researchers also constructed a list of the most important performance drivers of SCM digitalization:

- Speed at which goods are delivered is central for both suppliers and those involved in DSC.

- Need for operational agility with ease in adaption to changing circumstances.

- Global connectivity. Organizations need to deliver goods and services throughout the world quickly. This necessitates a truly global supply chain to enable organizations not only to deliver but also to ensure reaction at the local level.

- Real-time inventory. DSC makes warehouse management more efficient and monitors stock levels continuously with the help of arrays of sensors or via other advanced technologies.

- Intelligence. New generation technological enablers provide smart products that are equipped with enough computing power so that self-learning and autonomous decision-making could be enabled based on defined algorithms.

- Transparency. In a transparent supply chain, links in the chain do comprehend and act according to other links’ behaviors and needs.

- Scalability. Scaling supply chains up or down according to the required circumstances often creates a colossal struggle for organizations.

- Innovative. Excellence in DSC is a key feature so that DSCs are always open for a change. The world is being swamped with novel technologies at a seemingly faster rate than ever before.

- Proactive. DSC imposes proactive actions to prevent potential disruptions. This can be made possible not only through troubleshooting but also by identifying latent issues in advance through research

When comparing the traditional SCM practices and performance drivers, one can conclude that the performance drivers for digital supply chains partly overlap. It means digitalization has a role to improve the implementation of traditional activities. Especially, the goals concerning speed, global connectivity, real-time inventory, and innovativeness serve well the traditional SCM goals and practices referred to at the beginning of this paper. Also, the more recent SCM value drivers, flexibility, and agility are extremely well reached by digitally improved business practices. Transparency and visibility are often mentioned as features of an excellent supply chain. It is important to notice the small difference between information sharing and transparency/visibility. When sharing information, someone has to be active to do so. When we are talking about transparency, information is all the time available for stakeholders. Digitalization in the form of various information platforms serves as an excellent means to ensure transparency.

The latest trends in SCM

The newest, often futuristic discussion on SCM development includes two aspects: technological and organizational. The technological point of departure highlights the use of digital technologies to run and support SCM practices and processes. For example, the following trends have been predicted (Gartner, 2022):

- Hyper-automation; the use of digital technologies to automate supply chain tasks and processes

- Digital supply chain twin; to build a digital twin of a supply network for the purposes of multi-enterprise orchestration

- Immersive experience and application; the use of VR and MR to offer customers and employees an advanced experience of reality

- Edge ecosystems; the use of edge technologies to allow people to make informed, reliable, secure, and agile decisions at the edges of enterprises

- Supply chain security; security concerning machines, processes, information, data, and intellectual property

- Environmental, social, and governance (ESG); the evaluation of an organization’s governance in terms of social and environmental sustainability

- Embedded AI and analytics; to offer decision-makers real-time information, analytic intelligence, and visualization for the purposes of effective decision making

As the above trends are based on technological opportunities, the future-oriented discussion on SCM also includes organizational aspects. Two somewhat related ideas have been presented: The SCM control tower (e.g. Gartner, 2020 and supply chain-as-a-service (Ivanov, Dolgui & Sokolov, 2022). If the SCM control tower is understood as an organizational solution (not as an application or a platform), it means someone to take the responsibility for the orchestration of an entire supply chain. It is clear that only the most powerful corporations possess such power. It also is possible to outsource that responsibility to a third party (e.g., a platform owner), who then offers supply chain-as-service. It is to be seen if these new organizational ideas on SCM became true.

Is there anything in common between traditional vs. present principles on SCM?

The current future-oriented discussion on SCM is dominated by a technological angle. It is a clear manifestation of the digital transfer of business and society, which is a powerful trend today. However, if one looks behind the technology, it is possible to find something that has lasted as important drivers for supply chain performance through the years: integration and cooperation. Information and knowledge sharing, coordination of activities, integrated NPD, trust, and communication were the cornerstones of successful SCM already in the 1990s. Today, advanced technology is seen as means to increase and deepen supply chain integration and cooperation. Supply chain transparency and increasing visibility necessitate trust among supply chain partners. Blockchain as a technology offers a new type of trust, based on universal openness and traceability.

Besides the technological changes, the organization of SCM has changed, too. In the 1980s and even in the 1990s, SCM was clearly a firm-specific activity centered around procurement and purchasing. In late 1990 the idea of partnerships as integrated and cooperative business relationships enlarged the idea of SCM with, for example, by the principles of value co-creation. Customer relationship (CRM), as well as supplier relationship management (SRM), highlighted the development towards a more integrated and cooperative SCM. Now, if the current ideas of supply chain-as-a-service will appear to be realistic, the development of SCM will consist of three phases: firm-centered, collaborative, and outsourced.

From a managerial perspective, it is clear that a firm-centered SCM is easy to manage because organizational authorization gives SCM managers a legitimized position. In a cooperative SCM environment, a firm-centered authoritative SCM was not possible and it was replaced by cooperative practices. Today, when we talk about the orchestration of business ecosystems, the managers’ visible hand does not reach all the parties of an ecosystem effectively. Ecosystems rather compare to markets, where the invisible hand of the market mechanism coordinates activities. From that perspective, an ecosystems-viewpoint to SCM may not be realistic from a managerial perspective. A more realistic picture of modern SCM would be a multi-enterprise network where firms are managed in networks (instead of the management of networks) through the principles of transparency and visibility.

Jakamo as a supply chain platform is originally designed on the idea that each firm is the center of its own network. In the past and even today, the majority of inter-organizational activities consist of information, physical and financial flows between customers and suppliers. Taking the dyadic business relationship as the basis of the network, it is easy to enlarge the view towards multi-enterprise networks consisting of both bi- and multilateral relationships. In that way, supplier networks remain manageable as firms manage themselves in networks. Digital supply chain integration in terms of information transparency makes this possible.

References

Gülçin Büyüközkan*, Fethullah Göçer (2018). Digital Supply Chain: Literature review and a proposed framework for future research. Computers in Industry, 97.

Terpend, Regis; Tyler, Beverly B; Krause, Daniel R; Handfield, Robert B. (2008). BUYER-SUPPLIER RELATIONSHIPS: DERIVED VALUE OVER TWO DECADES. Journal of Supply Chain Management; Vol. 44, Iss. 2, (Apr 2008): 28-55.

E-book: Supplier Experience

Supplier Experience – The Fundamentals of Modern Supplier Collaboration is a carefully crafted guide that presents the concept of Supplier Experience through six practical lenses. Download your free copy!

Recent Posts

- Jakamo Business Central ERP Connector Now Available in Microsoft Marketplace

- Insta Group strengthens supplier collaboration and sustainability efforts with Jakamo

- TECHSAVVY MEDIA: Supply chain expert – Relationships with your suppliers are key to greener manufacturing

- Fastems Advances Supply Chain Sustainability with Jakamo

- Jakamo achieves ISO 27001 certification