Cutting Costs or Driving Value Creation?

On my last posting I took the liberty to define Supply Chain Collaboration (SCC) as a method to utilize the knowhow of your partner companies and optimize the resource utilization in your supply chain to increase end customer value. I am waiting for someone to propose a shorter definition, but until that we’d need to stick with it. This time it’s time to take a look into some ways and means how to actually utilize the theme to increase value.

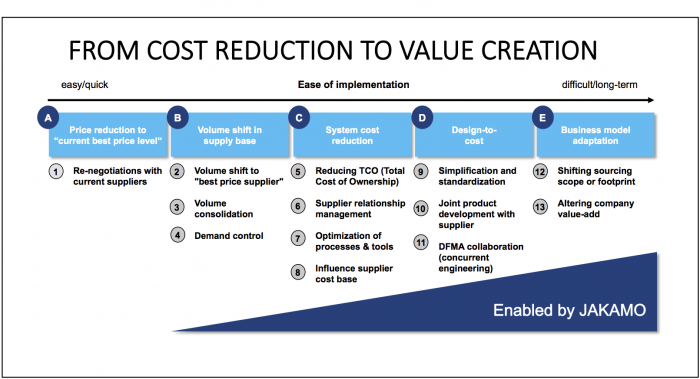

Below table introduces to some headlines from strategic SCM levers. On the left-hand side there’s the price/cost reduction part, where you squeeze the margins, use your power, force your supplier to reduce its prices or you change to new suppliers and start managing the spend. This is not where supply chain collaboration is needed. When you move further on to the right-hand side, the more difficult it gets and more collaboration is needed. This is also where you need to have the prerequisites, which I introduced in my last blog posting, in place and where communication and information sharing are the key.

Take DFMA as an example. You need to put some basic requirements in to use:

- Cross-functional teams (include members from various companies, disciplines and roles)

- Concurrent product realization (working on several different product or process elements simultaneously)

- Incremental information sharing (all information in all stages need to be shared within the team)

- Integrated project management (PM is the god. Responsibility is not abdicated once one element is finished)

It’s a complex, hard to manage –kind of a activity. How to make it into success?

McKinsey & Company introduces 6 steps to successful supply chain collaborations:

- Collaborate in areas where you have a sold footing

- Turn win-lose situations into win-win opportunities with the right benefit-sharing models

- Select partners based on capability and strategic alignment, not just size

- Invest in the right infrastructure and people

- Jointly manage performance and measure impact

- Collaborate for the long term

I would highlight and argue that to accomplish this, the outmost critical key to success is information. To have it. To manage it. To build on top of it. To share it. This is where collaboration is needed and this is where modern information sharing is required.

What would You prefer. Reduce or create? Cost or Value?

Matti Manner

CEO of Prohoc Ltd

Chairman of Jakamo Limited

E-book: Supplier Experience

Supplier Experience – The Fundamentals of Modern Supplier Collaboration is a carefully crafted guide that presents the concept of Supplier Experience through six practical lenses. Download your free copy!

Recent Posts

- Jakamo Business Central ERP Connector Now Available in Microsoft Marketplace

- Insta Group strengthens supplier collaboration and sustainability efforts with Jakamo

- TECHSAVVY MEDIA: Supply chain expert – Relationships with your suppliers are key to greener manufacturing

- Fastems Advances Supply Chain Sustainability with Jakamo

- Jakamo achieves ISO 27001 certification